mwahab1@lsu.edu

Office: 3270F PFT

(225) 578-5823

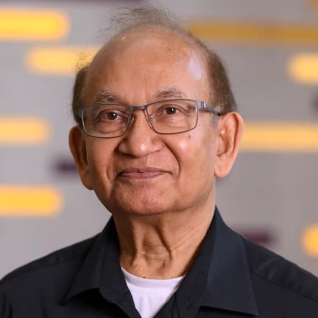

Muhammad A. Wahab

Professor, Mechanical Engineering

Formosa Plastics Endowed Professorship

PhD, University of Alberta, Canada (1984)

Expertise

Fatigue and fracture mechanics • composite materials • computational weld mechanics • structural stability • stress analysis • weld characterization for Friction-Stir-Welding.

Biographical Sketch

Dr. M. A. Wahab earned a “Master of Science in Engineering” from the University of New Brunswick, Canada and a PhD in Mechanical Engineering from the University of Alberta, Edmonton, Canada in 1984. Afterward he moved to Australia and worked as a Faculty in Mechanical Engineering from 1985 to 2001 at four different Australian universities (RMIT University- Melbourne, University of Tasmania-Hobart, Central Queensland University-Rockhampton, and Adelaide University-Adelaide). Subsequently he joined Louisiana State University (LSU), Baton Rouge-Central campus, USA in 2002 in Mechanical Engineering. Currently he has an endowed professorship “Formosa Plastics Distinguished Professor of the College of Engineering” at Louisiana State University. Dr. Wahab’s research interest encompasses the general areas of Weld modeling, Composite materials mechanics, Fatigue & Fracture modeling, and Materials characterization. Dr. Wahab was a founding member for the Australian “Cooperative Research Centers for Materials Welding & Joining (CRC-MW&J)” from 1992-1997 and contributed to strategic research initiatives of this Australian CRC. Dr. Wahab’s current research interests are in the areas of weld processing, especially in Friction Stir Welding (FSW) and has a US Patent jointly with his Research group, “On-line phased array ultrasonic testing for Friction-Stir-Welding (Patent # 11351628, - 07 June-2022). Dr. Wahab has successfully mentored 15-PhDs, and 19-Masters Theses; and has attracted several research grants from Federal and State Agencies including NASA-SLS, NAS-EPSCOR, US-NRC, US DOE, and an Education grant from NSF-GK-12 Program.

Key Publications

-

Davies, H.G. and Wahab, M.A., “Ensemble Averages of Power Flow in Randomly Excited Coupled Beams,” Journal of Sound and Vibration, Vol. 77, No. 3, pp. 311-321, (1981).

-

Nguyen, T.N. and Wahab, M.A., “A Theoretical Study of the Effect of Weld Geometry Parameters on Fatigue Crack Propagation Life,” Engineering Fracture Mechanics, Vol. 51, No. 1, pp. 1-18, (1995).

- Oehlers, D.J., Ghosh. A., and Wahab. M.A., “Residual Strength Approach to Fatigue Design and Analysis,” Journal of Structural Engineering of the American Society of Civil Engineers (ASCE-Structural Division), Vol. 121, No. 9, pp. 1271-1279, (1995).

- Loghman, A. and Wahab, M.A., “Creep Damage Simulation of Thick-walled Tubes Using the Theta Projection Concept,” The International Journal of Pressure Vessels and Piping, Vol. 67, Issue 1, pp. 105 -111, (June-1996).

- Nguyen, T.N. and Wahab, M.A. “The Effect of Residual Stresses on Fatigue of Butt-Joints,” Welding Journal, Welding Research Supplement, American Welding Society, pp. 55s-61s, (1996). http://www.osti.gov/scitech/biblio/218537

- Konka, H.P., Wahab, M.A., and Lian, K., “The Effects of Embedded Piezoelectric Fiber Composite Sensors on the Structural Integrity of Glass Fiber-Epoxy Composite Laminate,” Smart Materials and Structures, Vol. 21, No. 1, pp.015016 (9pp.) (2012). doi:10.1088/0964-1726/21/1/015016, URL: http://stacks.iop.org/0964-1726/21/015016

- Dewan, M.W., Liang, J., Wahab, M.A., Okeil, A.M., “Effect of Post-Weld Heat Treatment

and Electrolytic Plasma Processing on Tungsten Inert Gas Welded AISI- 4140 alloy

steel,” Materials and Design, 54 (2014) 6–13, http://dx.doi.org/10.1016/j.matdes.2013.08.035,

http://www.sciencedirect.com/science/article/pii/S0261306913007796 -

Dewan, M.W., Huggett, D.J., Liao, T.W., Wahab, M.A., Okeil, A.M., “Prediction of tensile strength of friction stir weld joints with adaptive neuro-fuzzy inference system (ANFIS) and neural network,” Materials and Design, Volume 92, 15 February 2016, Pages 288–299.

- Aziz, S.B., Dewan, M.W., Huggett, D.J., Wahab, M.A., Okeil, A.M., and Liao, T. W.,

“A fully coupled thermomechanical model of friction Stir Welding and Numerical studies

on Process parameters of lightweight Aluminum Alloy joints”, Acta Metallurgica Sinica

(English Letters), Vol. 31, pp.1-18, https://doi.org/10.1007/s40195-017-0658-4., First

published online: 4 Oct., 2017.

Available online at: http://link.springer.com/journal/40195 - Huggett, D.J., Dewan, M.W., Wahab, M.A., Liao, T.W., Okeil, A.M., “Control of principal processing parameters for “defect suppression model” for fixed pin friction-stir-welding (FSW), Elsevier Encyclopedia of Comprehensive Materials Processing, Second Edition. Reference Module in Materials Science and Materials Engineering, 25th August 2023. Pages-(1-13). Online available website: file:///C:/Users/mwahab1/Downloads/3-s2.0-B9780323960205000984-main%20(1).pdf. 2023, Elsevier Ltd., https://doi.org/10.1016/B978-0-323-96020-5.00098-4